Typically the switch opening point will be approximately one psi lower than the closing point. The range for the pressure switch closing and opening points is 11-23 psi. The primary purpose of these switches is to help the PCM/TCM detect when clutch circuit hydraulic failures occur. The PCM/TCM relies on three pressure switches to monitor fluid pressure in the L/R, 2/4, and OD hydraulic circuits. In addition to the periodic testing, the solenoid circuits are tested if a speed ratio or pressure switch error occurs. It no spike is detected, the circuit is tested again to verify the failure. An inductive spike should be detected by the PCM/TCM during this test. Each solenoid is turned on or off depending on its current state. The continuity of the solenoids and circuits are periodically tested. This allows transaxle limp-in (P, R, N, 2) in the event of an electrical failure. The 2/4 and UD solenoids are normally applied, which by design allow fluid to pass through in their relaxed or off state. The result is an apply or release of a frictional element. When a solenoid is energized, the solenoid valve shifts, and a fluid passage is opened or closed (vented or applied), depending on its default operating state. The PCM/TCM energizes or operates the solenoids individually by grounding the return wire of the solenoid needed. The solenoids receive electrical power from the Transmission Control Relay through a single wire. Likewise, the pressure switches can only be service by replacing the assembly. The solenoid assembly also contains pressure switches that monitor and send hydraulic circuit information to the PCM/TCM.

Transmission solenoid manual#

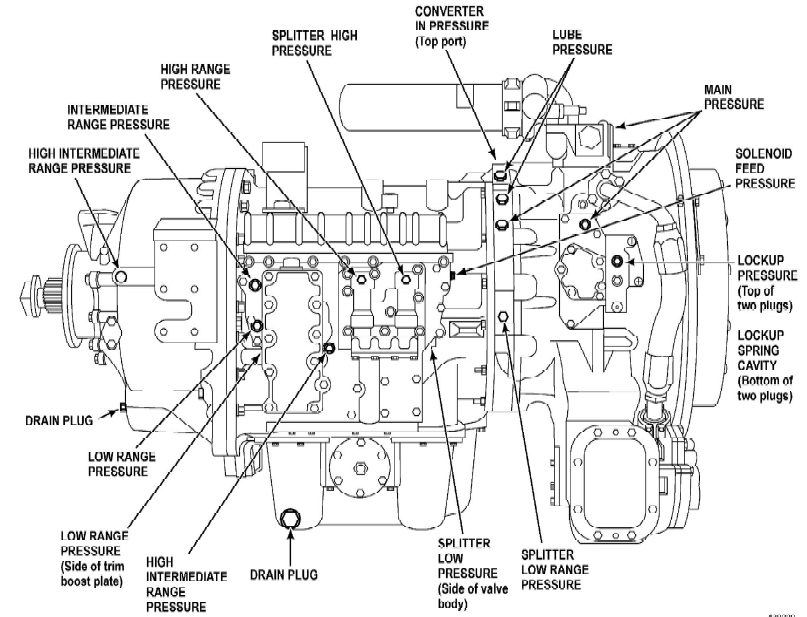

The reverse clutch is controlled by line pressure from the manual valve in the valve body The solenoids are contained within the Solenoid/Pressure Switch Assembly, and can only be serviced by replacing the assembly. The assembly consists of four solenoids that control hydraulic pressure to the LR/CC, 2/4, OD, and UD friction elements. 350) is external to the transaxle and mounted to the transaxle case. The Solenoid/Pressure Switch Assembly (1) (Fig. Hydraulic leak into clutch circuit with near-zero volumeįig. Transmission Effects: These CVIs that are out of range are usually set with other DTCs, which indicates an internal transmission problem. The clutch volume should be between 24 and 70. The transmission temperature must be above 43☌ (110☏). The UD clutch volume is updated when doing a 4-3 or 4-2 shift. The clutch volume should be between 40 and 150. The OD clutch volume is updated when doing a 2-3 shift. The clutch volume should be between 20 and 77. The 2/4 clutch volume is updated when doing a 1-2 shift. The clutch volume should be between 35 and 83. The transmission temperature must be between 21 - 49☌ (70 - 120☏). The LR clutch volume is updated when doing a 2-1 or 3-1 coast down shift. The following are typical clutch volumes, the clutches may be damaged if the volumes are greater or less than the specified below: As the clutch friction material wears, the volume of fluid needed to apply the clutch increases. Theory of Operation: The volumes of the transmission fluid needed to apply the friction elements are continuously monitored and learned for adaptive controls. You will need an advanced scan tool to monitor the status of the switches and solenoids actions in the transmision. You will need to have someone do pressure testing on the transmission to see if there is sufficient pressure. Since you replaced one of the solenoids and it did not work, the issue most likely is internal.

0 kommentar(er)

0 kommentar(er)